Table of ContentsHow Roof Flashing WorksWhat Is Roof Flashing And Why Is It Important? - A Roofer ExplainsWhat Is Roof Flashing?What Is Roof Flashing And Why Is It Important? - A Roofer Explains

The water then streams from the roof slopes down the valley and into the gutters. One of the most typical methods water can enter into houses is by method of chimney. However, chimney flashing assists to efficiently stop water from entering. The way this is done is by installing L-shaped metal pieces in between shingles courses all along with a chimney.

Likewise called the saddle roofing system. Its function is to produce a slope that keeps water from having the ability to accumulate behind a chimney. Then, a large piece of flashing covers the cricket roofing and runs alongside the shingle run on top of it. Generally, it is mortared directly onto the chimney itself.

On the side of the chimney, counter https://blogfreely.net/sharap2n4h/b-table-of-contents-b-a-0143 flashing is also mortared onto either the stone or brick course and runs down on top of the step flashing. Finally, chimney flashing is mortared on the front of a chimney. It is going to be mortared at the lowest part of the roofing slope.

This is where any water may run. And this is how chimney flashing works. As we've discovered, flashing assists protect your roofing system and house from entering water. This likewise includes piping and vents that sit atop your roof. On most homes, you'll normally have at least a few vents or piping.

Roof Flashing -- A Basic Guide To The Different Types

For vents, the flashing is generally cone-shaped with a flange at the base. It is worked into the roof shingles as the roofing is initially applied. The method it works is that there is a main grow opening that is made of metal. It also may be with a rubber compression that covers around PVC piping.

Ultimate Guide To Roof Flashing

Ultimate Guide To Roof Flashing

The center will slip over the vent pipe. This is where it's installed beneath the roofing. In doing so, this makes water run out of and away from the pipeline opening. For assistance with roofing flashing for your home, please do not hesitate to call us. As a preferred roofing business in San Antonio, you can rest ensured we will do the job right for you.

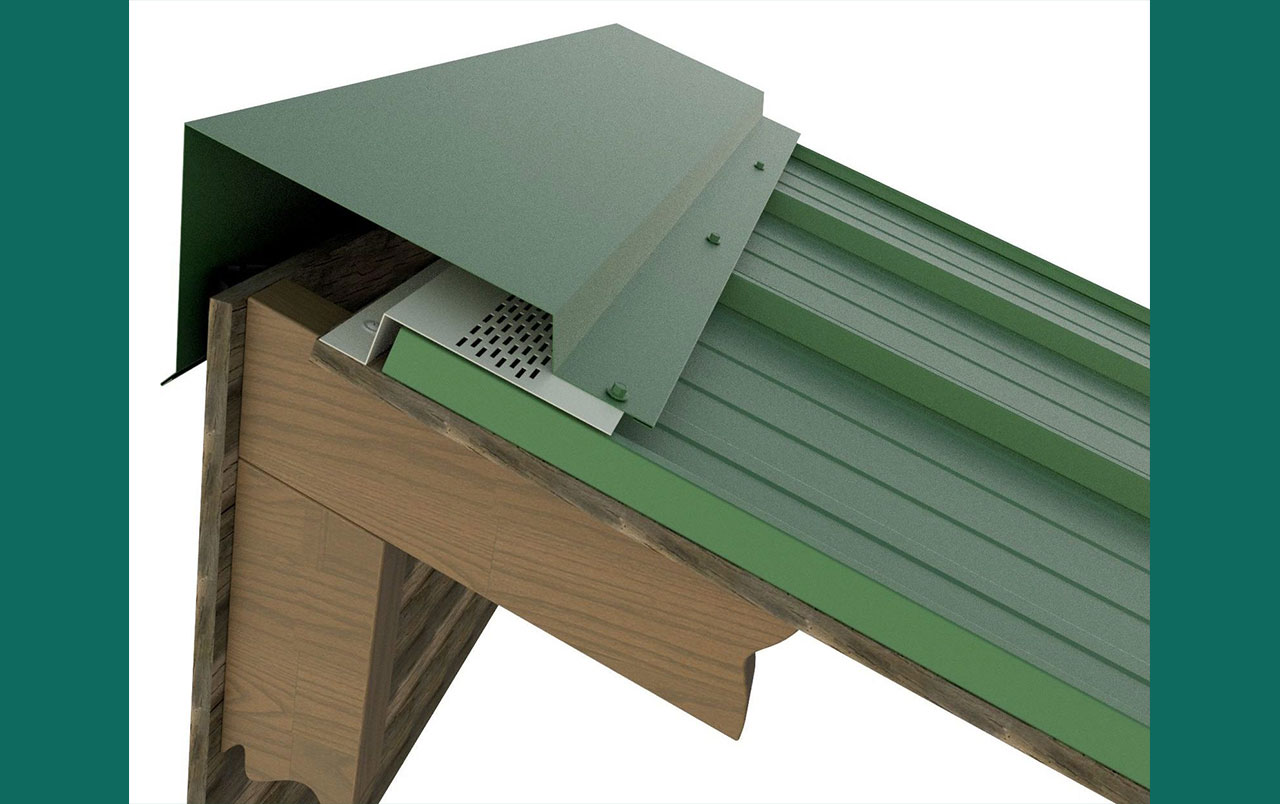

Weatherproofing joint in between a stone chimney and a tile roofing system on a building in Jersey, Channel Islands. The lead flashing is viewed as light gray sheets at the base of the chimney. Flashing refers to thin pieces of invulnerable product installed to prevent the passage of water into a structure from a joint or as part of a weather condition resistant barrier system.

Metal flashing materials include lead, aluminium, copper, stainless-steel, zinc alloy, and other products. The origin of the term flash and flashing doubt, however may come from the Middle English verb flasshen, 'to spray, splash', associated to flask. Counter-flashing (or cover flashing, cap flashing) is a term utilized when there are two parallel pieces of flashing employed together such as on a chimney, where the counter-flashing is built into the chimney and overlaps a replaceable sothern Arizona roofers - DC Roofing of Arizona piece of base flashing.

What Is Roof Flashing & Why Is It Needed When Installing

The up-hill side of a chimney may have a small gable-like assembly called a cricket with cricket flashing or on narrow chimneys with no cricket a back flashing or back pan flashing. Flashing might be let into a groove in a wall or chimney called a. Before the accessibility of sheet items for flashing home builders used creative approaches to lessen water penetration such as angling roofing system shingles far from the joint, placing chimneys at the ridge, constructing enter the sides of chimneys to shake off water and covering joints between roofing products with mortar flaunching.

therefore making buildings more durable and lowering indoor mold problems. Furthermore, flashing is crucial to guarantee integrity of the roof prior to a photovoltaic panel installation. In builders books, by 1832 Loudons An Encyclopdia of Home, Farm, and Villa Architecture and Furnishings ... provides direction on setting up lead flashing and 1875 Notes on Building Building and construction gives detailed direction and is well shown with methods still utilized today.

Why Is Roof Flashing So Important?

Why Is Roof Flashing So Important?

https://www.google.com/maps/embed/v1/directions?key=AIzaSyAT8ig6vIZpArpz5aokN-7eevoH-Unfy0Y&origin=32.1433135,-110.9163409&destination= AZ 85706&mode=driving

Exposed flashing is usually of a sheet metal and concealed flashing might be metal or a versatile, adhesive backed, product especially around wall penetrations such as doors and window openings. In earlier days, birch bark was periodically used as a flashing product. Most flashing products today are metal, plastic, rubber, or fertilized paper.

Metal flashing need to be offered with growth joints on long runs to avoid deformation of the metal sheets due to expansion and contraction, and need to not stain or be stained by adjacent materials or react chemically with them. An essential type of potential chain reaction between metal flashing products is galvanic rust.

What To Do About A Leaking Roof Flashing

Likewise, Aluminum and zinc flashing can not be utilized in contact with pressure treated wood due to quick deterioration. Aluminum is also damaged by damp mortar and damp plaster. Salt spray in coastal areas might speed up deterioration; so stainless-steel, copper, or coated aluminum are suggested flashing products near seawater.

The different types have various application temperature level ranges, material adhesion compatibility, chemical compatibility, levels of volatile organic compounds, and resistance to ultraviolet light exposure. No flexible flashing materials are developed for long-lasting exposure as are metal flashing products. [] Adhesive backed materials are practical throughout setup, however such adhesives are not intended for long-term water-resistance. [] Copper is an exceptional material for flashing since of its malleability, strength, solder-ability, workability, high resistance to the caustic effects of mortars and hostile environments, and long life span (see: copper flashing).

DC Roofing of Arizona

Tucson, AZ

(520) 979-9095

https://www.dcroofingarizona.com/

https://www.google.com/maps?cid=13615084232433183222

Considering that flashing is costly to replace if it stops working, copper's long life is a significant cost benefit. Cold rolled (to 1/8-hard mood) copper is advised for a lot of flashing applications. This product uses more resistance than soft copper to the stresses of growth and contraction. Soft copper can be defined where severe forming is needed, such as in complicated roofing shapes.